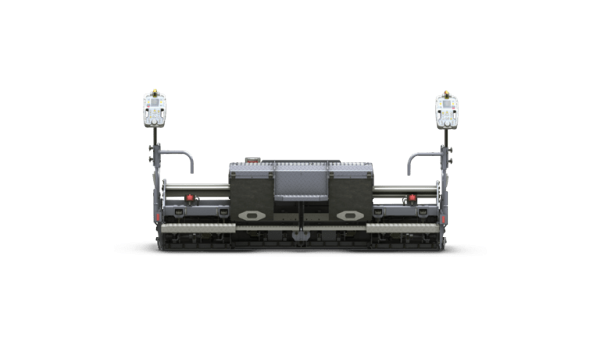

Vogele AB 340

| Make | Vogele |

| Model | AB 340 |

| Type | Extending Screeds |

How can we help?

Description

The perfect Compact Class screed

The extending screed AB 340 is the ideal screed for compact pavers of the 1000 and 1300 class. With a basic width of 1.8 m and a maximum pave width of 5 m, the screed is ideal for building combined foot and cycle paths, minor rural roads and narrow roads or squares.

Specifications

- Basic screed weight : 1,550 kg

- Basic screed weight Screed: AB 340 TV

- Compacting systems: V, TV

- Compacting systems Frequency (max.): 50 Hz

- Compacting systems Speed (max.): 1,700 U/min

- Compacting systems Stroke (TV): 4 mm

- Compacting systems Vibrators (V): eccentric vibrators

- Depth (in transport position) Depth: 1.1 m

- Depth (in transport position) Screed : AB 340 TV

- Pave Basic width: 1.8 m

- Pave Bolt-on extensions: 80 cm

- Pave Cut-off shoes: 0.5 m – 1.2 m

- Pave Extra bolt-on extensions: (TV)

- Pave Hydraulically adjustable: 1.80 m to 3.40 m

- Pave Minimum pave width: 5 m

- Profile Settings Crown adjustment: -2.5 % to 3 %

- Profile Settings Height adjustment, extending units: -20 mm to 25 mm

- Profile Settings Version: mechanical

- Screed Heating Heating rods: on screed plates and in tamper bars

- Screed Heating Output generation: three-phase AC generator

- Width (with side plate): 1.8 m

Features

- Electric screed heating: VÖGELE has put its faith in electric screed heating for decades. This extensive experience, in combination with continuous further development, means that VÖGELE screeds are now brought to temperature quickly and evenly.

- Compaction technology: VÖGELE sets standards in compaction values during paving: cutting-edge technology and the most advanced materials guarantee the outstanding performance and reliability of VÖGELE compaction technology. This applies to all VÖGELE compacting systems, from vibrators all the way to the VÖGELE high compaction system with tamper and pressure bars.

- Manufacturing technology Screeds: VÖGELE screeds feature leading-edge technology made possible by state-of-the-art production processes. The first of these processes, the precision cutting to shape of extremely wear-resistant sheet steel, takes place on laser cutting stations. Robots which operate continuously to a consistently high standard ensure long-lasting, stable welds.

- Telescoping system Extending Screeds: The operating principle of all VÖGELE Extending Screeds is the single-tube telescoping system. Even at maximum extension, half of the three-part, generously-sized telescoping tube is clamped, ensuring optimum stabilization. As the guiding system is arranged at a high level, this prevents any contact with paving mix.