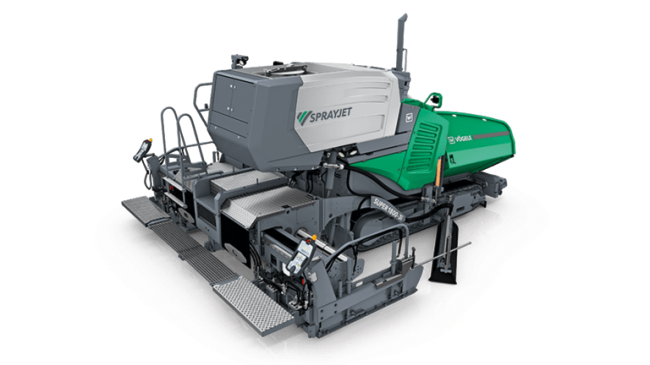

Vogele Super 1800-3i SprayJet

Special Class

How can we help?

(208) 324-2900

Features

-

ErgoPlus 3: Even the very best machine with the most advanced technology can only really show its strengths if it can be operated easily and as intuitively as possible. At the same time, it should offer an ergonomic and safe working environment for the operating team. Therefore, the ErgoPlus 3 operating concept focuses on the operator.

-

PaveDock and PaveDock Assistant: A constant supply of mix is essential for producing a level, high-quality pavement. That's why VÖGELE developed the PaveDock Assistant for their “Dash 3” generation of pavers. This exceedingly efficient system greatly facilitates communication between the paver operator and the driver of the feed vehicle, and it ensures that the mix is supplied to the paver safely and without jolts. Used in combination with the PaveDock push-rollers, PaveDock Assistant contributes greatly to process safety during the transfer of the mix.

-

VÖGELE EcoPlus: The philosophy behind the machine concept of the Premium Line road pavers is "Lower consumption – lower emissions – lower costs". The VÖGELE EcoPlus low-emissions package combines a number of individual measures to reduce the fuel consumption and noise levels to a significant extent.

-

SprayJet Technology: VÖGELE’s SprayJet technology has proved its value for many years and is used for pavement rehabilitation and construction in markets around the world.

-

AutoSet Plus: With AutoSet Plus, we have enhanced the efficiency, the convenience and thus the quality of key job site processes. AutoSet Plus has two handy automatic functions. The two functions of AutoSet Plus automate routine tasks, allowing work processes to be carried out more quickly and with greater control. This in turn means that construction projects can be completed faster and more reliably.

Specifications

Augers : |

2 |

Augers Diameter: |

400 mm |

Augers Drive: |

separate hydraulic drives, proportional control |

Augers Lubrication : |

centralized lubrication system, electrically-driven grease pump |

Augers Speed: |

84 U/min |

Augers Standard height: |

hydraulically adjustable by 15 cm |

Augers Version: |

with replaceable auger blades, auger rotation reversible |

Conveyors : |

2 |

Conveyors Drive: |

separate hydraulic drives, proportional control |

Conveyors Speed: |

34 m/min |

Conveyors Version: |

with replaceable feeder bars, direction of conveyor temporarily reversible |

Drive ECO mode output: |

350 kW / 1600 U/min |

Drive Emission Daily noise exposure level : |

80 dB |

Drive Emission Sound power level : |

108 dB |

Drive Engine: |

liquid-cooled 6-cylinder diesel engine |

Drive Exhaust emissions after-treatment: |

DOC, SCR |

Drive Exhaust emissions standard: |

European exhaust emissions standard 4, US standard EPA Tier 4f |

Drive Fuel tank: |

300 l |

Drive Manufacturer : |

Cummins |

Drive Nominal output: |

125 kW / 2000 U/min |

Drive Type: |

QSB 6.7 - C164 |

Material Hopper Feed height (bottom of material hopper): |

615 mm |

Material Hopper Hopper capacity: |

13 t |

Material Hopper Push-Rollers Positions : |

can be adjusted in a forward direction by 75 mm |

Material Hopper Push-Rollers Standard: |

oscillating |

Material Hopper Width: |

3,265 mm |

Maximum Laydown Rate: |

700 t/h |

Operating Total Weight: |

23,020 kg |

Operating Weight Screed: |

AB 600 TP1 |

Screed Compacting systems: |

TV, TP1 |

Screed Heating: |

electric, thermostat-controlled |

Screed Layer thickness (up to): |

30 cm |

Screed Maximum width : |

6 m |

Screed Power Supply: |

Three-phase AC generator |

Screed Type: |

AB 600 |

SprayJet Emulsion tank: |

insulated hopper walls |

SprayJet Number of spray bars: |

5 |

SprayJet Number of spray nozzles: |

24 |

SprayJet of which pivoting spray bars: |

2 |

SprayJet Optionally with additional tank: |

7,100 l |

SprayJet Rate of spread : |

0.3 kg/m² to 1.6 kg/m² |

SprayJet Screed heating: |

electric, thermostat-controlled |

SprayJet Spray cone: |

120 ° |

SprayJet Spray pressure (up to): |

3 bar |

SprayJet Spray width: |

2.55 m to 6.00 m |

SprayJet Standard: |

2,100 l |

Undercarriage Ground Contact : |

3658 mm x 400 mm |

Undercarriage Pave speed (up to): |

25 m/min |

Undercarriage Track Tension Adjuster : |

spring assembly |

Undercarriage Traction Drive Crawler Tracks : |

separate hydraulic drives with electronic control |

Undercarriage Travel speed (up to): |

4 km/h |