John Deere 544 G-Tier Mid-Size Wheel Loader

Mid-Size Wheel Loaders

How can we help?

(208) 324-2900

Specifications

CAPACITIES - Breakout - Bucket, kgf (lbf): |

10916 (24066) |

CAPACITIES - Fuel Tank, ltr (gallons (US)): |

290 (76.6) |

CAPACITIES - Heaped Capacity, m³ (yd³): |

2.1 (2.75) |

CAPACITIES - Hydraulic Tank, ltr (gallons (US)): |

86 (22.7) |

CAPACITIES - Pump Flow - 1, lt/min (gallons (US) / min): |

189 (50) |

CAPACITIES - Pump Type: |

Piston |

CAPACITIES - Ride Control System: |

Optional |

CAPACITIES - System Pressure, bar (PSI): |

251.66 (3650) |

DIMENSIONS - Ground clearance, mm (inches): |

410 (16.1) |

DIMENSIONS - Height - Over Cab, mm (ft/in): |

3270 (10 ft 9 in) |

DIMENSIONS - Height - Pivot Pin, mm (ft/in): |

3830 (12 ft 7 in) |

DIMENSIONS - Reach - At 2130mm 45° Dump, mm (ft/in): |

1440 (4 ft 9 in) |

DIMENSIONS - Wheelbase, mm (ft/in): |

2930 (9 ft 7 in) |

DIMENSIONS - Width Over tires - Std, mm (ft/in): |

2460 (8 ft ) |

DRIVELINE - Displacement, ltr (Inches³): |

6.8 (414) |

DRIVELINE - Emission Rating: |

EPA Tier 4 / EU Stage V |

DRIVELINE - Engine Manufacturer: |

John Deere |

DRIVELINE - Engine Model: |

PowerTech PVS 6068 |

DRIVELINE - Engine Output - Net, kW (hp): |

125 (168) |

DRIVELINE - Front Differential Type: |

Locking |

DRIVELINE - Parking Brake - Type: |

Wet Multi Disc |

DRIVELINE - Rated Speed, rpm: |

1800 |

DRIVELINE - Rear Differential Type: |

Open |

DRIVELINE - Service Brake - Actuation: |

Hydraulic |

DRIVELINE - Service Brake - Type: |

Wet Disc |

DRIVELINE - Tire size - Standard: |

20.5 R25 |

DRIVELINE - Torque, Nm (lbf / ft): |

696 (513) |

DRIVELINE - Transmission Type: |

Powershift |

WEIGHTS - Operating Weight, kg (lbs): |

12993 (28646) |

Maximize machine versatility with coupler and bucket options

JRB 416 coupler with bucket attachment

JRB 416 coupler with bucket attachment

544 G with forks

544 G with forks

544 G loading a mixer

544 G loading a mixer

544 G with side dump bucket

544 G with side dump bucket

Customers can choose between pin-on bucket options as well as Hi-Vis/ISO and JRB style couplers that accept both K and L-series and Performance Tiering buckets and attachments.

- Machine utilization and fleet versatility can be maximized by easily switching between attachments with optional equipped coupler

- Optional third or fourth-function hydraulics allow additional attachments to be equipped on the machine for maximum versatility

- General performance pin-on and coupler buckets are available in 2.1- or 2.3-m³ (2.75- or 3.0-cu. yd.), with additional options available through field kits

- 1524-mm and 2438-mm (60- or 96-in.) Hi-Vis/ISO coupler fork frames with 1,219-, 1524-, or 1828.8-mm (48-, 60-, or 72-in.) tine lengths are available for order through field kits

Operate with ease with user friendly controls

Operator’s view in a 544 G-tier loader

Operator’s view in a 544 G-tier loader

Sealed switch module (SSM) mounted to right front frame

Sealed switch module (SSM) mounted to right front frame

Third-function hydraulics in operation

Third-function hydraulics in operation

Integrated Forward Neutral Reverse (FNR) switch on joystick

Integrated Forward Neutral Reverse (FNR) switch on joystick

The 544 G-tier controls were designed with operators of all skillsets in mind. The simple setup and functionality means operators can put the machine to work quicker and easier.

- Pilot controls on the 544 G-tier are intuitive to operate and will be familiar to both novice and experienced operators

- Automatic shifting of the 4-speed forward, 3-speed reverse transmission occurs on the fly for ease of operation for operators of all skill sets

- Optional front locking differential provides additional traction in muddy or softer ground conditions

- In-cab adjustable boom-height kickout, return to carry, and return to dig can be easily activated from the convenient SSM, speeding production in repetitive applications

- Clutch cutoff allows for the delivery of full engine power to the hydraulics when crowding a pile and using the brakes which increases cycle times and productivity. A sensor integrated into the brake pedal cues the cutoff in the transmission to occur during braking so operators don’t have to press a button to disengage the transmission

Proven and reliable major components that enable maximum reliability and durability

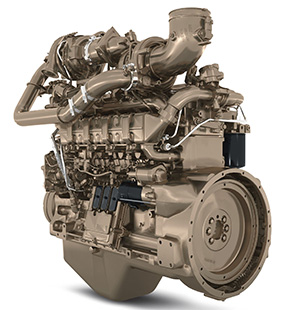

John Deere PowerTech™ 6.8L Engine

John Deere PowerTech™ 6.8L Engine

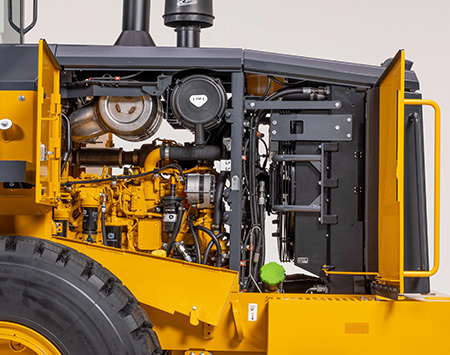

Left side engine access

Left side engine access

Right side engine access

Right side engine access

Front TeamMate™ V Axle

Front TeamMate™ V Axle

Built on over 50 years of experience producing and supporting wheel loaders, the 544 G-tier features a high commonality of components found in other Deere loaders that are designed and tested to meet John Deere Standards including the engine, transmission, and axles.

- The John Deere PowerTech™ 6.8L engine is designed to improve cooling and provide high cylinder and piston ring durability

- John Deere TeamMate™ V axles contain pressure lubed input bearings and brake disks. These features enhance cooling and extend component life, which helps lower total cost of ownership

- Extended service intervals lower the cost of maintenance over the entire life of the machine

- Auto Idle and Auto Shutdown reduce engine speed or turn engine off completely after a period of inactivity to save fuel and warranty hours

Comfortable and straightforward cab design

View of standard cab operation station

View of standard cab operation station

Optional air-ride suspension seat

Optional air-ride suspension seat

Ergonomically designed foot pedals

Ergonomically designed foot pedals

Adjustable cab controls

Adjustable cab controls

The cab on the 544 G-tier was designed to provide different levels of comfort to operators depending on the machine application. The setup ensures that operation of the machine is straightforward with easy to access machine settings and features.

- Standard mechanical or optional air-ride suspension provides varying levels of comfort offerings to better fit different applications

- Open floor storage on the left side of the seat gives operators room to place lunch boxes or personal items out of the way of foot pedals and controls

- Joystick controls, foot pedals, and sealed-switch module have all been ergonomically placed to ensure maximum comfort

- Standard AC/Heat system keeps operators comfortable in all climates

- High-definition, adjustable monitor with built-in ability to view diagnostic trouble codes

Service and support capabilities you’ve come to expect from John Deere and our world class dealer network

Hinged doors on both sides of the machine for ground-level access and service

Hinged doors on both sides of the machine for ground-level access and service

Left side service doors

Left side service doors

Hydraulic sight gauge

Hydraulic sight gauge

127-mm (5-in.) liquid-crystal display (LCD) monitor

127-mm (5-in.) liquid-crystal display (LCD) monitor

The 544 G-tier is backed by John Deere’s world class dealer network that provides warranty support, maintenance, and has the parts on the shelf needed to allow maximum uptime. Attributes related to servicing and supporting the 544 G-tier are no different than those experienced today on all other models of John Deere equipment.

- All daily service points including fuel are conveniently grouped on the left side of the machine at ground level for easy access

- Easy to view transmission and hydraulic sight gauges

- Hinged doors provide wide-open access to the engine, the cooling system, and other components

- 127-mm (5-in.) LCD multifunction color monitor displays detailed diagnostic trouble code descriptions, sensor values, and circuit testing for troubleshooting

- John Deere Connected Support, JDLink™, Service Advisor Remote, and Expert Alerts enable sharing of real time machine data and alerts. Fleet managers and dealers can view codes and data remotely before dispatching a technician to a jobsite, increasing uptime and lowering costs

Economical without sacrificing performance

544 G Wheel Loader

544 G Wheel Loader

The 544 G-tier wheel loader was designed to provide an economical solution to the market, without having to sacrifice on the known productivity that John Deere loaders are known for

- The 544 G has similar productivity to the 544 P and other competitors in its size class in common applications like V-pattern loading and material stockpiling

- Optional High-Lift linkage adds an additional 356 mm (14 in.) of hinge-pin height over standard linkage enabling the loader to be utilized in more applications

- Optional auto reversing fan and axle oil cooler ensure major components are kept clean and cool throughout the day to keep up with the demands of the most grueling applications